Will Nigeria's Ajaokuta Steel Mill Renewal With Russia’s Support Shape Its Industrial Future?

18:42 20.05.2024 (Updated: 10:13 21.05.2024)

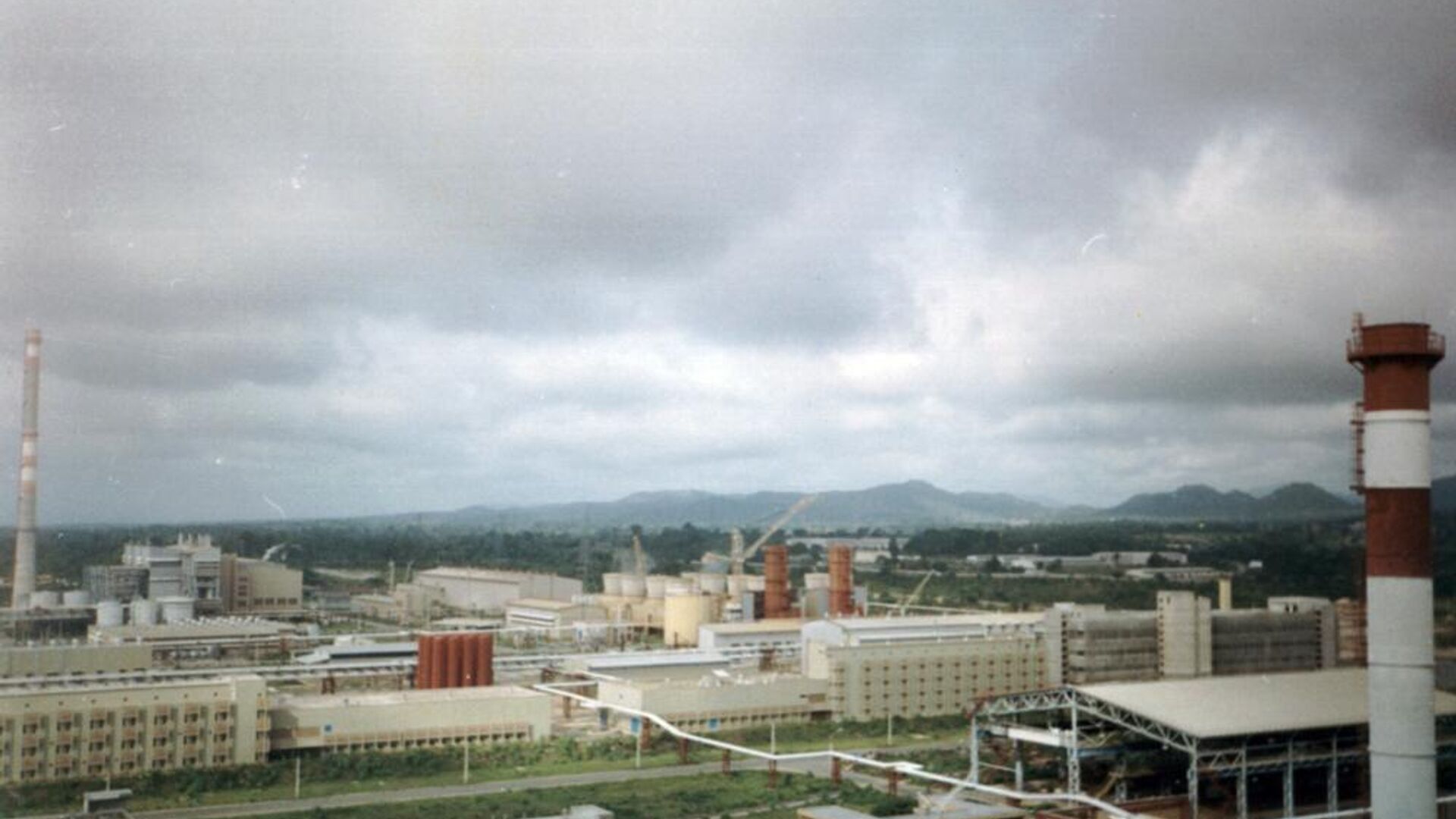

© Photo

Subscribe

Longread

Nigeria's President Bola Tinubu said that reviving the Ajaokuta Steel Complex is fundamental to his campaign promise of economic diversification, stimulating foreign direct investment, and creating job opportunities - a commitment expected to inject $1.6 billion annually into the country's economy.

At the Africa-Russia Summit in Sochi, Russia, in October 2019, Presidents Muhammadu Buhari and Vladimir Putin struck a deal to revamp the Ajaokuta steel complex, reportedly with funding from Afreximbank and the Russian Export Bank.

Sputnik Africa takes a historical assessment of the planning, development, and management of Nigeria’s Ajaokuta Steel Company as it seeks Russia’s support to revive the plant for economic diversification and resilience.

Origin & Strategic Location of the Steel Plant

The Ajaokuta Steel Company is located in the heart of a local government area named after the town in Kogi State's Central Senatorial District for several reasons:

The area boasts a green environment and is adjacent to the vital water source of the Niger/Benue River confluence, a perfect match for a steel project of this magnitude,

Ajaokuta naturally abounds with steel deposits,

It is situated at a major crossroads linking the 18 states of Nigeria's various geopolitical zones.

Historically, the town is renowned for its mining activities, including its proximity to Itakpe, a site rich in commercially viable iron deposits for steel manufacturing.

Initial Attempts at Developing Nigeria’s Steel Sector

In 1958, Nigeria began planning for large-scale steel production to boost technological advancement. From 1960 to 1966, President Nnamdi Azikiwe and Prime Minister Tafawa Balewa engaged Western firms to assess its feasibility.

Studies by Western countries revealed skepticism concerning the cost-effectiveness of a steel plant during that time due to the high cost of technological and associated infrastructural development, lack of manpower and domestic market, scarcity of hard coal, absence of suitable technology, and coercive nature of diplomatic and economic interests.

Collaboration With the USSR

Two separate studies conducted in 1967 by United Nations Industrial Development Organization (UNIDO) and Soviet steel experts showed a compelling market demand for steel in Nigeria but uncovered abundant iron ore at Itakpe Hills, coking coal (hard coal) at Lafia, and heat-resistant clay at Oshiele and Onibode

The Soviet Union aimed to build trust with Nigeria, leading to collaboration on geological surveys for iron ore and coking coal (hard coal). This resulted in the USSR’s Tyazhpromexport (TPE) assessing resources for the Ajaokuta steel facility and recommending a blast furnace/basic oxygen method, which prompted Nigeria to establish the Nigerian Steel Development Authority (NSDA) in 1971 to oversee steel plant development and related research.

“In my first presidency, there was the general belief that steelmaking was at the heart of industrialization. India had built a first steel plant with Russian help, and they built their second almost without help. We thought we needed to achieve that, but we did not have enough money to do it alone. So, we went to the Soviet Union, and there we obtained the best deal on offer: we got a free loan from the Russian government, and we commissioned an experienced Soviet contractor, TPE, to design and build the plant,” according to insights shared by Olusegun Obasanjo, Nigeria’s former military head of state and president, back in 2021.

Nigeria’s comprehensive partnership with Russia's Tyazhpromexport, termed 1979 The Global Contract, emphasized "technology transfer" in its approach to personnel training involving 1,584 engineers, technicians, and skilled workers. Russia trained Nigerian workers in steel plants for nine months.

The training was part of a six-year cooperation agreement involving cultural, bilateral, and technical aspects. Nigerian graduates worked as technicians in Russian plants during this period. The program focused on hands-on experience in operating and maintaining steel plants. Once operational, the Ajaokuta Steel plant was expected to employ around 10,000 workers, according to a 1992 published research in the Nigerian Journal of International Affairs, 1998.

Nigeria’s Efforts at Industrialization and Privatization

Since the 1970s, efforts to operationalize Nigeria's Ajaokuta Steel Complex have encountered numerous setbacks.

In 1980, the involvement of Western firms complicated the project, introducing conflicting economic and professional ideologies and halting the construction. Notably, the dependence on contractors for civil works tied the progress of ASCL to their pace, impacting the installation of process equipment.

Starting in 1980, the Ajaokuta Steel Company Limited enterprise aimed to complete its project within four years and five months but faced substantial budget overruns. By 1983, operational finishing mills for light rods and sections marked progress, with full plant integration achieved by 1990. By October 1993, ASCL stood at 98 percent completion, providing direct employment to over 1,000 Russians and 3,500 Nigerians. However, TPE's withdrawal from the project in 1994 stemmed from Nigeria's breach of contractual obligations.

In 2002, President Obasanjo started a public-private partnership (PPP) for the Ajaokuta project with Japan’s Kobe Steel. Ispat Industries took over in 2004, backed by India’s Global Steel Holdings Limited (GSHL). Following the breach of the concession in 2008, GSHL sued Nigeria at the International Chamber of Commerce, ending in a settlement in 2016, with Nigeria paying over $495 million in 2022.

Nigeria Turns to Russia for Help

To underscore the essence of realizing Nigeria’s industrial ambitions, the country’s immediate past president, Buhari, who initiated the restoration of the dilapidated Ajaokuta steel facility after years of unsuccessful attempts by past administrations, sought new concessionaires to inject the necessary investments. Subsequently, Buhari established the Ajaokuta Presidential Project and Implementation Team (APPIT) to oversee the revamp of the project. After taking over from his predecessor, President Tinubu followed in their footsteps by inaugurating a five-person ministerial committee to ensure the project's accomplishment.

Striving to bolster Nigeria's industrialization efforts, Nigeria's current Minister of Steel Development, Prince Shuaib Audu, addressed the press last February and unveiled an ambitious three-year roadmap for reviving the Ajaokuta Steel complex. He underlined President Tinubu's unwavering commitment to renew the country's steel industry, positioning it as a linchpin in Nigeria's broader industrialization agenda.

The minister revealed that technical analysis and expert evaluation data highlighted the need for a whopping $2 billion to $5 billion to revive the ASCL. This is expected to inject $1.6 billion into Nigeria's economy, potentially creating about 500,000 direct and indirect employment opportunities. He pointed out that 90 percent of the nation's present steel demands come from imports, which the current administration is committed to reversing.

On April 25 this year, Nigeria’s steel development minister met with the representatives of a Russian consortium, including TPE/Rostec, Novostal, and indigenous firm Proforce, in Abuja. He urged them to develop a blueprint promptly for reviving the steel facility. Audu announced plans to visit Moscow at the invitation of TPE and other consortium partners to discuss securing about $2 billion in funding for the project.